FOOD AND PLANT BUILDING ACHIEVES CODE COMPLIANCE WITH AEROSEAL

CASE STUDY

Food and Plant Building

Mt. Albert, Auckland

The Site:

The Mt Albert campus, close to the city, is the Research facility's head office. The site features new purpose -built buildings and glasshouses alongside several historical building and employs around 300 staff including 180 research staff.

The Problem:

The consultancy firm who visited the site are renowned for their stringent enforcement of air flow criteria. After spending the better part of a week directing the subcontractor to apply mastic to the ductwork, Adrian of 1st Mechanical called in the LIMS Aeroseal team to aeroseal the ductwork.

The Solution:

Two days later we had our van onsite. All entry points to the ductwork were in the same room which made for smooth transitions from one injection point to the next. All five runs were sealed to an excellent standard (one of them being the best result we’ve ever achieved: 1.6L/s @ 500 Pascals). The whole job was done in one day; hope we get to work with these guys again, they were great.

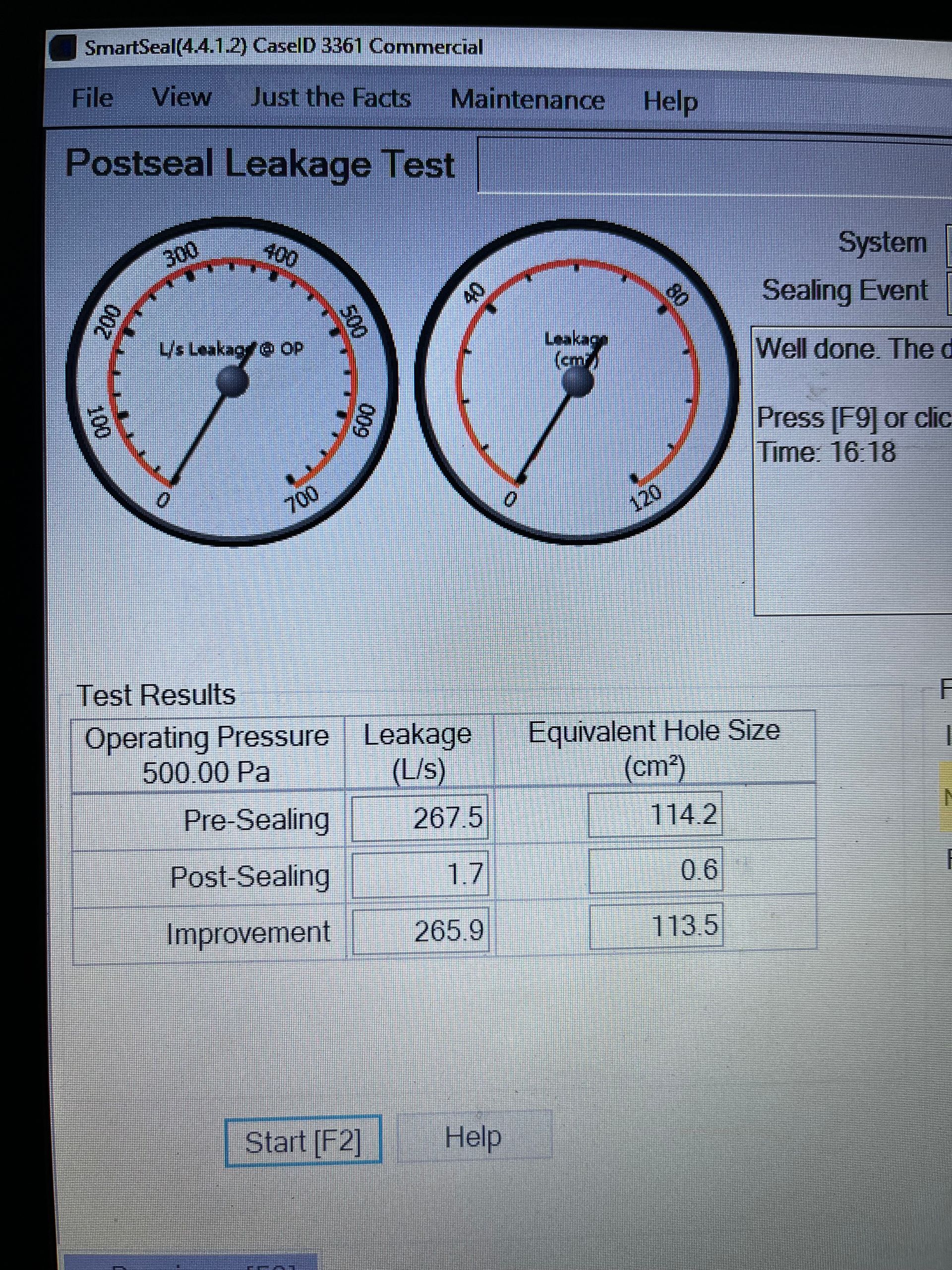

| Run number | Initial leakage @ 500 Pascals | Postseal leakage @ 500 Pascals |

|---|---|---|

| 1 | 152.64L/s | 1.93L/s |

| 2 | 267.41L/s | 1.65L/s |

| 3 | 136.93L/s | 1.60L/s |

| 4 | 172.78L/s | 2.69L/s |

| 5 | 201.89L/s | 4.95L/s |

| Project Overview | |

|---|---|

| Building: | Plant and Food Building Research Centre |

| Location | Sandringham, Mt. Albert, Auckland |

| Aeroseal Contractor | LIMS Aeroseal |

| General Contractor | 1st Mechanical |

| Consultant | BECA |

| Goal | Reduce leakage and pass inspection |

| Results | Sealed ductwork with more than 95% reduction in a single day. The building was compliant and passed inspection. |

To Learn More About Improving The Comfort, Indoor Air Quality, and Energy Efficiency Of Your Building Call 0226759426 or Email info@aeroseal.nz