MARRIOTT HOTEL ATLANTA ENHANCES HVAC SYSTEM USING AEROSEAL®

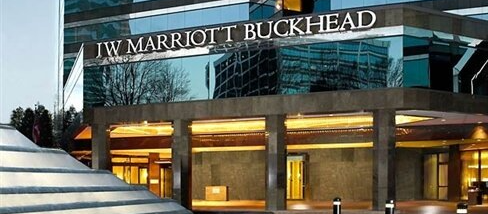

JW MARRIOTT ATLANTA BUCKHEAD

At a JW Marriott hotel, inadequate exhaust led to musty odors. Accessing and repairing the problem had proven to be logistically and economically impossible.

Until recently, sealing leaky ventilation shafts (a.k.a. air ducts or ductwork) has been a non-starter for most commercial buildings across the country. The expensive and disruptive demolition typically involved in finding, accessing, and sealing those leaks using hand sealing (e.g. mastic, tape) made remediation measures impractical at best. As a result, most buildings in the U.S. today are plagued by the poor indoor air quality (IAQ) and energy efficiency issues associated with duct leakage. Thanks to Aeroseal, contractors have a simple, non-intrusive solution, in the form of an aerosol-based computer-controlled duct sealing method that seals leaks with more confidence and more cost-effectively than hand sealing alone.

While the JW Marriott hotel in Atlanta’s affluent Buckhead district has always been a model of elegance and luxury, owners of the 28 year-old building continued to struggle with HVAC issues associated with the air leaks in the air ducts. Inadequate exhaust led to musty odors that plagued the building for years. With long ventilation shafts embedded behind the building’s structure, accessing and repairing the problem had proven to be logistically and economically impossible.

PROJECT OVERVIEW

BUILDING

JW Marriott Atlanta Buckhead

LOCATION

Atlanta, Georgia

AEROSEAL CONTRACTORS

Aeroseal Southeast

GOAL

Improve building exhaust. Minimize disruption

BEFORE AEROSEAL

4,670 CFM of leakage (total)

AFTER AEROSEAL

553 CFM of leakage

RESULTS

Reduced leakage by approximately 88%; guests were unaware of the remediation work being conducted

While the JW Marriott hotel in Atlanta’s affluent Buckhead district has always been a model of elegance and luxury, owners of the 28 year-old building continued to struggle with HVAC issues associated with the air leaks in the air ducts. Inadequate exhaust led to musty odors that plagued the building for years. With long ventilation shafts embedded behind the building’s structure, accessing and repairing the problem had proven to be logistically and economically impossible. A consultant brought in to evaluate the situation found that exhaust levels differed substantially from floor to floor. Top floors received the full 40 CFM of exhaust they were designed to pull, while bottom floors received only 5 CFM or less.

Here’s what the consultant recommended: start by cleaning and sealing each of the ten 23-story ventilation shafts running down the length of the building. Searching for a duct sealing solution, the hotel engineers learned about Aeroseal duct sealing and decided it was the right choice for the job. “We looked at several options and the aeroseal technology stood out as being the most economical and non-intrusive process,” said Frank Atkins, the hotel’s director of engineering.

To Learn More About Improving The Comfort, Indoor Air Quality, and Energy Efficiency Of Your Building Call 0226759426 or Email info@aeroseal.nz