IMPROVING AIR TIGHTNESS IN AN EXISTING SYSTEM

Improving air-tightness at the new ACC building.

In mid-October, LIMS Aeroseal was contacted by Talat of McAlpine Hussmann. The kitchen extract riser at 179 Collingwood Street in Hamilton (soon to be ACC’s new building) was not meeting its target at commissioning. We’ve worked together with McAlpine on three projects so were well pleased to get the call.

After induction the technician and myself set up on the roof. It was the smoothest job we’ve ever done, the only complication was having to lug our gear (including the 130kg compressor) down the stairs at the end. A big thank you to Vimal of McAlpine for lending his muscles!

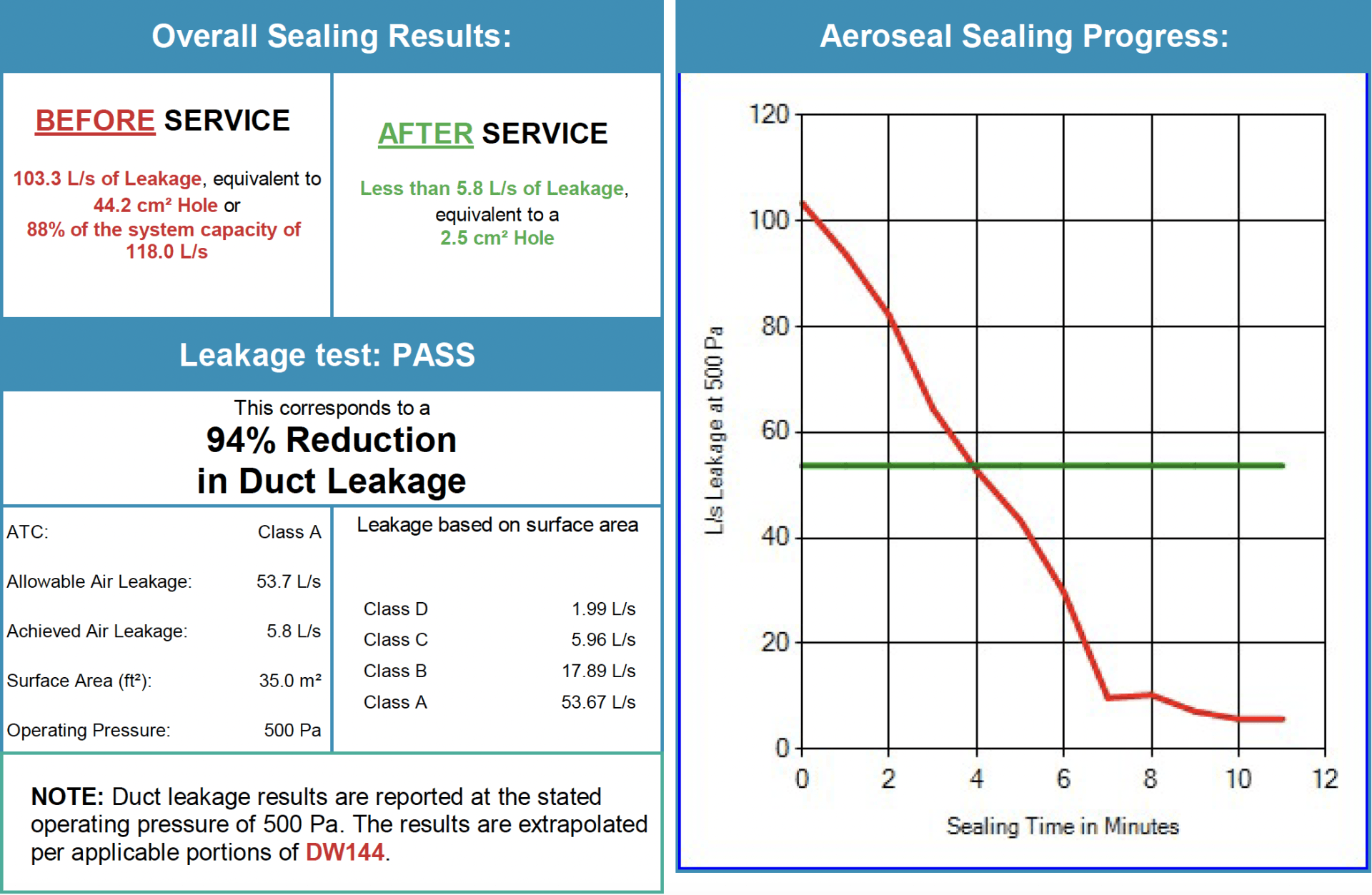

Anyway, with an operating pressure of five hundred pascals the initial leakage was 103.3L/s. We got it down to 5.8L/s = 94% improvement on airtightness. Job done. To put this in a way easily pictured in the mind’s eye: initial leakage added up to a 44 square cm hole; final leakage was the equivalent of a 2.5 square cm hole. These figures are great to use because they are agnostic to air pressure.

Thank you Talat and we look forward to working with you again soon.

PROJECT OVERVIEW

BUILDING

The new ACC building

AEROSEAL CONTRACTORS

LIMS Aeroseal

CONTRACT ENGINEER

McAlpine Hussmann

GOAL

To improve air tightness and get the system approved

BEFORE AEROSEAL

103.3 L/sec of Air leakage equivalent to hole size 44.2cm2

AFTER AEROSEAL

5.8 L/sec of Air leakage equivalent to hole size 2.5cm2

RESULTS

Achieved 94% improvement in air tightness

To Learn More About Improving The Comfort, Indoor Air Quality, and Energy Efficiency Of Your Building Call 0226759426 or Email info@aeroseal.nz